DWS returns to T.Gold

High resolution, definition, accuracy, detail precision. The performance of DWS printers is unmatched in the sector thanks to the continuous research conducted by the R&D department, which designs not only the 3D printers but also the materials (meltable and functional) and management software: a fully integrated system that guarantees complete control over all the processes and components necessary for the realization of the objects.

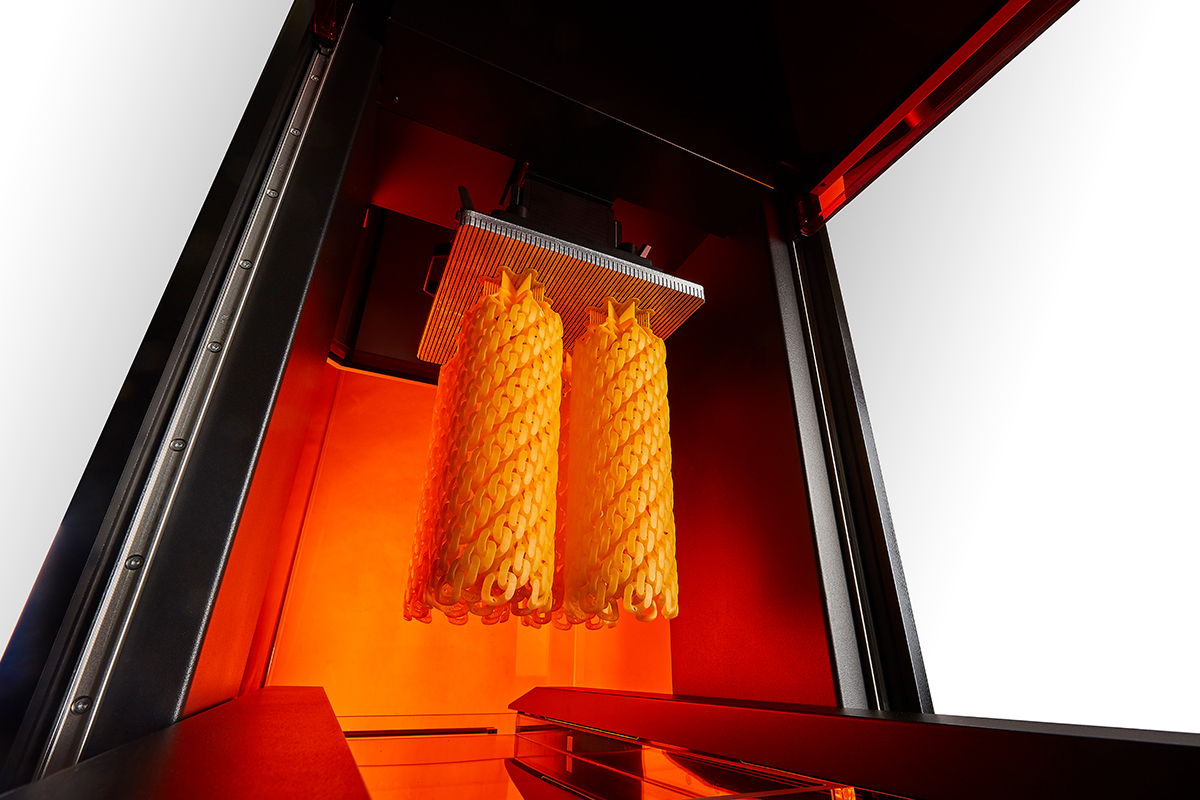

Among the new applications and technologies stand out cluster 3D printing for direct investment casting (XCluster), printing of already stretched chains (XCluster Chain) and printing of finished products characterized by textures and transparent surfaces, which reproduce ceramics or suitable for customization through classic treatments.

Thanks to the combination of materials, 3D stereolithography printer and specially designed software, the workflow becomes completely digital and automated. This increases the productivity of companies by reducing time to market, decreasing production times and costs.